Name of the parameter | Explicit description of the crucial, technical parameters of IGUs dessicants according to PN-EN ISO 1279:2018 | Justification for the importance of the desiccant's specific, technical parameters |

|---|---|---|

Dust content | Dust content, despite not being assessed within PN-EN ISO 1279-4:2018 norm is an indispensable parameter that affects usability of selected desiccant in IGU and its price. The dust content greater than 50 ppm (50 mg/kg) is unacceptable because of the possibility of elutration of the smallest particles within IGU space and possibility to settle on the glass panel | Unfortunately, dust content, is not specified in PN-EN ISO 1279-4:2018 norm, however, based on numerous complaints and dialogues with IGU providers, it may significantly decrease the quality of certain desiccant. Small particles of dust, can be elutrated or even deteriorate the filling process, hernce knowing its exact amount (mostly not more than 50 µg/kg = 50 ppm) is profitable from both technical perspecitve and economical point of view. Its content in certain amount of desiccant should be close to the smallest amount or even not appear. In addition high dust content can cause malfunactions of automatic filling machine |

Diameter of a single granule | A straight line passing from side to side through the centre of a body or figure, especially a circle or sphere. The parameter that governs the spherical geometry of a single granule and its morphology | Diameter of the single granule seems to be crucial from the point of view of the proper filling of the IGU frame. The smaller the diameter the better the filling of the frame appear in respect to the geometry of the frame and greater active area for water vapor sorption is available, hence there is no condensation possible |

AWAC - Available Water Adsorption Capacity | One of the key parameter that ensures there is no condensation within IGU and low humidity environment is sustained during reasonable, economic lifetime. Expressed as the percentage [%] by weight of the mass of the desiccant | Since facilitation of the low humidity and water-vapor free environment within the IGU, the AWAC is the key parameter that describes the perfomance of the selected desiccant which has to be simultaneously effective and selective toward gaseous chemicals that occur in IGU. It is worth to mention, that the stability of the desiccant in the function of time is neglected but indispensible when proper AWAC is to be maintained. |

Bulk density | Another important parameter that describes the certain mass of the selected desiccant that occupies certain volume. Expressed as [g/L] | As the spatial and complete filling of the frame by the desiccant is undeniable and desirable by IGU manufacturers, the bulk density describes how much of the material is needed to govern specific area within the window frame. Its importance lays in the need to know exactly how much of the material in needed to occupy certain space, which in further perspective translates to knowing how much of the material is needed and how much it would cost. |

Electrostatic charge | Electrostatic charge is also unspecified parameter in abovemnetioned ISO norm. Nevertheless, presence of electric charge is an effect of the chemical nature of the desiccant raw material. Molecular sieves used for the purpose of manufacturing of the desiccant garunles (mostly zeolites - skeleton aluminosilicates minerals) are composed of tetrahedral building units composed of silicon central atom bonded with oxygen atoms in the nods of the tetredr. Presence of aluminium may trigger heterovalent diadochy* phenomena, therefore Si4+ cations are replaced by Al3+ cations, which generates negative charge on the surface of the zeolite. | Electric charge is of importance for prospective use of certain desiccant because once attached to positively charged surface it may deteriorate the filling process and spoil the volumetric occupation of the IGU frame. |

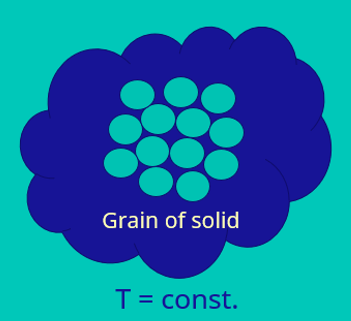

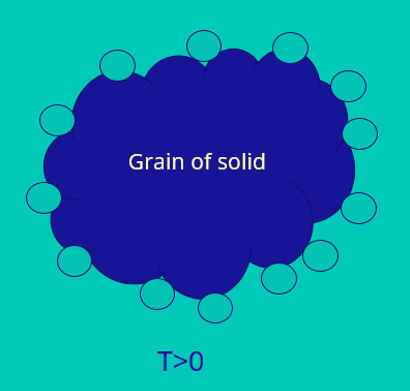

Delta T value (ΔT) | This parameter, described in PN-EN ISO 1279-4:2018 norm, regulates the amount of heat released by the specific amount of desiccant once liquid water is introduced to the sample, since adsorption is an exothermic process** (release of energy as heat is observable, hence water vapor is observable on the vessel's walls) | The delta T value can be an indirect measure to describe adsorption rate of the selected molecular sieve implemented as desiccant for IGUs. At the same time, the higher the spontaneous, momentary delta T value is the stronger the water adsorption efficiency is. |

Fenzi Molver | CRL MSD | Grace Phonosorb 551* | Siliporite NK 30 | Nanomol | Zeolan K | IG MOL 3000 | Vitrimol | XL8 Molsiv | Aqua-Sieve 3A | Eurosiv | GEWE-sorb | GLASMOL | ECO MOL | Natergy | |||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

L.p. | Parameter | Unit | |||||||||||||||

1 | Bulk density (EN 1279-4)**** | [g/dm3] | 800 | ≥680 | 750 | 780 | 880 | 830 | 835 | 850 | 740 | 710 | >700 | 790 | 700 | 770 | 840 |

2 | AWAC* (Available Water Adsorption Capacity) (EN 1279-4) | [% wt.] | ≥15.5 | ≥20.0 | 16.5 | ≥16.5 | ≥20.0 | ≥20.0 | ≥20.2 | ≥20.0 | >21 | >20 | >19 | >20 | >20 | >17 | ≥16 |

3 | LOI (Loss On Ignition) at 540°С | [%] | n.d.a.*** | n.d.a*** | 2 | ≤2 | ≤2 | ≤3 | ≤2 | ≤3 | n.d.a*** | n.d.a** | ≤2 | ≤2 | 1 | <2 | ≤1.7 |

4 | Dust content | [ppm]** | ≤40 | ≤30 | ≤25 | ≤70 | ≤20 | ≤20 | ≤50 | n.d.a*** | 22 | <30 | <30 | <50 | ≤30 | <50 | <50 |

5 | Delta T value (ΔT) | [℃] | 35 | ≥36 | n.d.a*** | 36 | ≥38 | ≥35 | ≥31 | ≥30 | n.d.a*** | ≥35 | >25 | ≥35 | ≥35 | >30 | >30 |

6 | Diameter of a single granule | [¢mm] | 0.5-1.0 | 0.5-1.1 | 0.5-0.9 | 0.7-0.9 | 0.5-0.8 | 0.5-0.7 | 0.5-1.2 | 0.5-1.15 | 1.0-1.68 | 1.3-1.7 | 0.5-0.9 | 0.5-0.9 | 0.7-1.3 | 0.5-0.85 | 0.5-1.25 |

7 | Gas desorption | [ml/g] | ≤0.30 | n.d.a** | 0.5 | 0.15 | 0.25 | 0.25 | 0.15 | n.d.a** | 0.2 | n.d.a** | n.d.a** | 0.2 | n.d.a** | 0.5 | n.d.a** |

ABSORPTION | ADSORPTION | |

|---|---|---|

|

| |

Definition | Assimilation of molecular species throughout the bulk of the solid or liquid | Accumulation of the molecular species on the surface rather than in the bulk of the solid or liquid |

Phenomenon | Bulk phenomenon | Surface interactions |

Heat exchange | Endothermic | Exothermic |

Temperature impact | Independent of T | Favourable in low T's |

Rate of the reaction | Occured at an unimform rate | Steadily increases until reachable equilibrum |

Concentration of the chemical indviduum | Uniform throughout the material | Concentration on the surface greatly differs from the one observed in the bulk |